Z-Saw Features

High quality materials

The blades of all Z-Saws are made from polished cold rolled high carbon steel strips which we source from prestigious manufacturers in the international market under strict quality control. The steel strips are as hard as HV 540 to 580 with 0.8 -0.9 % of carbon content , widely considered to be the best material for high quality saw blades featuring superb flexibility and durability.

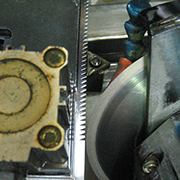

Perfectly ground teeth

The teeth of Z-Saw blades are ground using our self-developed automatic tooth grinding system using CBN grinding wheels. Even the smallest distortion will be automatically detected and carefully corrected. Through this process, the blades can be ground to perfectly parallel edges , ensuring that the teeth bite into the workpiece completely straight. This is almost impossible to achieve with hand-filed teeth.

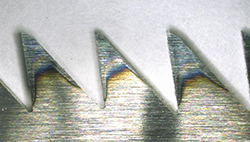

Custom tooth patterns

Z-Saw makes saw blades with several different basic tooth patterns (e.g. rip / cross / universal) each of which is applied to different saw blades with subtle variations depending on the use of each individual saw.

Cross

Rip

Universal

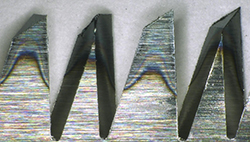

Sturdy hardened teeth

ZETSAW branded blades are made in-house. The teeth are hardened through a process called Hard Impulse. Treating the teeth in this way helps keep them sharp for much longer than conventional counterparts. The core of the blade remains both flexible and tough to prevent it from bending or buckling during use.