Tips on pull saw

Choosing the right saw for the job

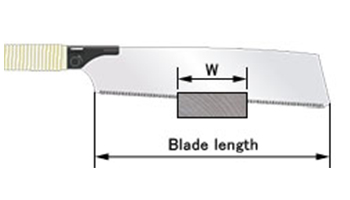

Length of blade

For efficient cross cut and universal cut sawing, the saw blade should be at least two but preferably three times as long as the workpiece (wood) to be cut.

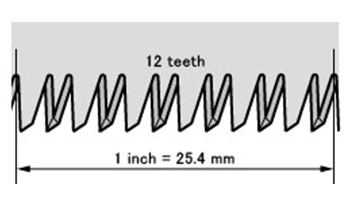

Teeth per inch

For a saw to work properly, it has to have a certain number of teeth within the wood it is cutting. Too many, the teeth fill up with sawdust and no longer cut effectively. Too few, the saw gets too hard to push through, leaves too rough a cut, and can tear out large chunks of wood with it.

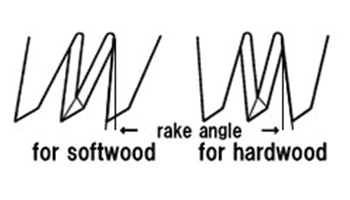

Rake angle

The ideal Rake angle, which means the attacking angle of the saw teeth to the wood, varies according to the density of the wood to be cut. For cutting wet or soft wood, the attacking angle of the teeth should be very sharp, so that the teeth can efficiently dig into the wood and will not slip in the kerf. In contrast, for cutting denser wood, the rake angle should be more obtuse than the teeth for cutting softwood. A larger cutting angle on the teeth can alleviate quick wear-out of the teeth, and make the saw easier to operate.

Choosing the right handle for the work

Long traditional rattan wrapped handle

The Japanese traditional handle can be held with two hands for a long steady cut, or for small precise cuts by holding the blade end of the handle with the fore finger resting along the back of the spine.

Short pistol grip

The short pistol grip can add strength behind the saw blade for relatively aggressive cutting, and makes it easier to control the sawing direction while cutting. The screw-fit type of saw handle can also be reversed to make the cutting line more visible.

Short straight handle

The short straight handle is ideal for use with relatively short saw blades for more balanced strokes.

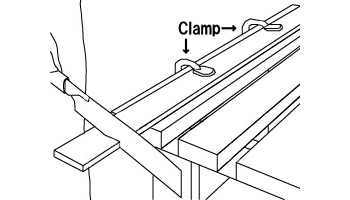

Solid grip

If you hold the work piece with a vice or clamp, sawing is much easier and both hands are available for more stable saw strokes. If you have to hold the work piece by hand, 70% of your force should be apportioned for holding and only 20% for sawing.

* Laying a rubber sheet under the wood to be cut can considerably reduce the force required to keep the work piece steady.

Start to cut

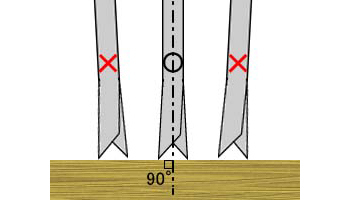

Place the teeth perpendicularly on the work piece

Saw blades have what is known as set, meaning that some teeth are bent slightly to the left and others to the right. It is important to try to equalize the numbers of right- and left-facing teeth in contact with the workpiece as if there is an imbalanced condition; the saw blade is drawn toward the loaded teeth. The best way to do this is to ensure that the blade is at right angles to the surface of the workpiece with as many teeth as possible in contact.

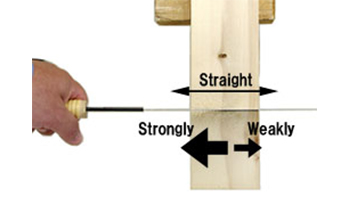

Pull to cut

Z-saws are all traditional Japanese pull saws, which are ground to cut wood while pulling the saw blade towards the user. On the opposite stroke-pushing, the saw teeth on the kerf should be kept touching the base of the groove because on the push stroke, the saw teeth will shove saw dust away and clear the sawing groove.

* Pressure on the saw blade should be minimized to not more than blade weight on the push stroke.

Straight sawing motion

Stroke the saw in a rhythm of 2-beats without stopping at the end of every stroke end. Continual strokes are produced by a steady swing repeated close to your body. Try not to move the handle up and down (when sawing a horizontal workpiece) or from side to side: just towards your body to cut and then lightly away from the body. Using a Saw guide can greatly assist in learning the proper sawing technique.

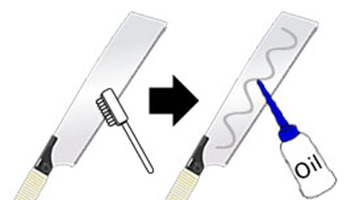

Maintenance & After use

After you have finished sawing, use a brush to clean out saw dust stuck in the gullet (space between the teeth), and oil the blade if it will not be used for some time for. Wrapping with VCI (Vapor Corrosion Inhibitor) paper or newspaper can very effectively prevent blade corrosion.

↑Page top